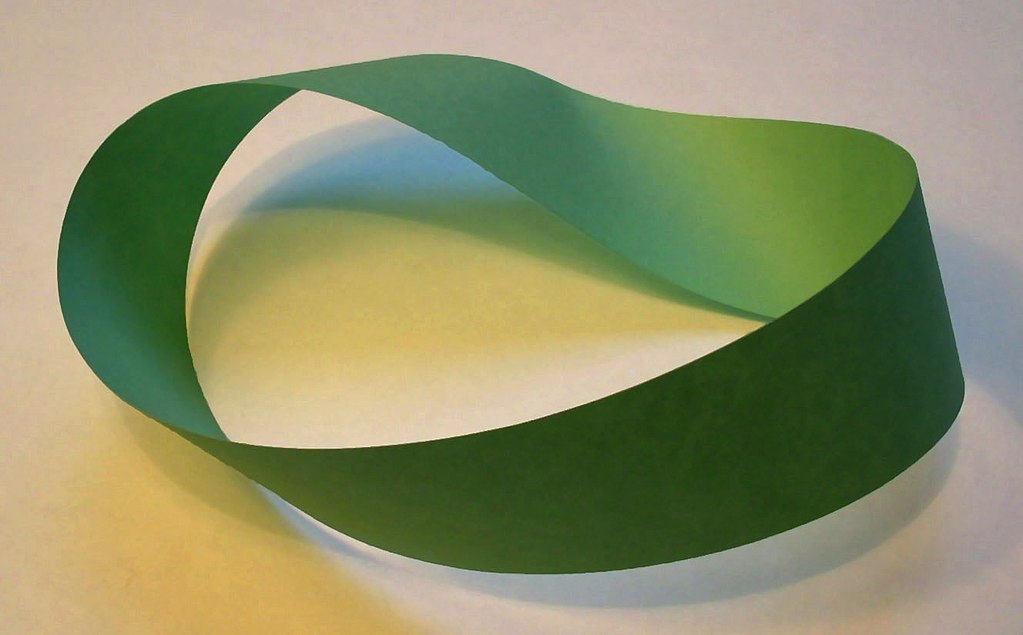

Möbius strip

en.wikipedia.org/wiki/Möbius_strip

http://mechproto.olin.edu/final_projects/average_jo.html

Fabrication

The first element of the system we created was the rigid outer gear. This part was produced with the rapid prototype technique of fused deposition modeling, an additive 3D printing method that uses heated ABS plastic to create parts layer by layer. Printing the outer structure in one piece took a number of days at the highest resolution setting, but it was the most reliable and cost effective method for creating a piece of its precision and complexity. The final product was rigid, gorgeous, and as precise as needed. With the outer gear printed, we could begin to produce and integrate the other components of our design.

The next part we focused on creating was the compliant inner gear. After a number of material and design revisions, the final inner gear was molded out of MoldStar 30, a soft yet durable silicone from Reynolds’ catalog. The inner gear was molded as a straight rack gear, removed from it mold, and manually twisted into a Mobius gear. In order to give the gear structure along its neutral axis, the inner gear was molded with a hollow plastic tube traveling through the middle of the silicone strip. When the gear was removed and shaped into a Mobius structure, we fed a pre-bent galvanized steel wire through the hollow tube, fixing the structure as a ring around which the silicone teeth could bend. The piece was then placed back into the mold and joined together into the final Mobius structure by pouring the last tooth with the same silicone mix.

The inner gear was produced using 3D-printed molds, which, just like the inner gear itself, had undergone a series of revisions to make them reusable yet breakable if the compliant material was difficult to remove safely. When used in conjunction with shellac and Mold Release, the bendable gear mold allowed us to safely and easily remove the silicone gear. Given the length of the gear and the size limitations of the 3D printer, the mold was produced in three pieces. The mold was designed to make the gear initially linear, so that all of the teeth had the same shape and were not biased by the curvature of the final Mobius shape.

With the outer and inner gears created, the next step was to create the planetary gears that would ultimately keep the inner gear on track. As with the inner gear, we created reusable 3D printed molds for the planetary gears. For the sake of precision and easy removal of the gears, the molds were designed as two parts with locating features that locked into each other. These molds fit together snugly and were open at the top to allow for easy and quick pouring. In order to ensure that there were no bubbles present in any of the gears during the molding phase, we put the urethane mix in a vacuum before pouring the individual gears. The final product was a stiff, yet bendable enough, planetary gear that interfaced with both the inner and outer gears well.

最新文章

- TweenMax参数说明

- 如何使用抓包工具fiddler对app进行接口分析

- 【Java】使用iText生成PDF文件

- LeetCode - 49. Group Anagrams

- spring bean中scope="prototype“的作用

- java9-2形式参数

- UVaLive 6609 Meeting Room Arrangement (贪心,区间不相交)

- XMLHttpRequest 使用概括

- 在Bash中,如何判断某个命令是否存在?

- 业务接口+UI层的设计(基于Castle实现的Repository)

- C#工作笔记

- VM虚拟机中安装Linux操作系统

- scrapy 快速入门

- 服务器 'xxxx' 已被定义为分发服务器。若要将该服务器重新配置为分发服务器,必须首先卸载现有的分发服务

- virtualenv与virtualenvwrapper虚拟环境

- html转js字符串拼接

- NYOJ 迷宫寻宝(一)

- 前端框架之Vue(2)-模板语法

- C#生成指定长度随机数

- Bean标签的常用属性

热门文章

- 转 Python——UnicodeEncodeError: 'ascii' codec can't encode/decode characters

- cpu乱序执行

- CI调试应用程序

- 用Linux完成Oracle自动物理备份

- js-html音乐播放

- 深入理解js中的立即执行函数(function(){…})()

- assigning to uiimagepickercontrollerdelegate from incompatible type

- weblogic运维时经常遇到的问题和常用的配置

- Android减少布局层次--有关Activity根视图DecorView的思考

- 记录一下:关于mysql数据误删除恢复的问题